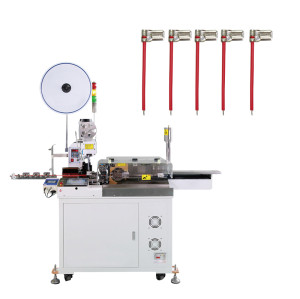

TR-HTX01 Single-head Sheathed Wire Tin-dipping Terminal Machine

- Model

- TR-HTX01

Item specifics

- Power

- AC220V/50HZ,

- Application

- sheathed wire stripping end tin dipping mac

- Feature

- Stable Performance

- Warranty

- 1year

- Control

- Servo and Step motor

Review

Description

TR-HTX01 Single-head Sheathed Wire Tin-dipping Terminal Machine

Power Supply:AC 220V 50Hz

Dimensions & Weight:2300x900x1500mm, 450kg

Main Functions:Wire cutting, double-end stripping, single-end crimping, single-end twisting and tinning

Equipment Capacity:500 cycles/hour; within OD5.0 (2-4 cores) 1500pcs/h; within OD5-5.5 (5-7 cores) 1000pcs/h; within OD5.5-6.5 (7-10 cores) 500pcs/h

Front Stripping Length:10-45mm (extendable for customization)

Front Core Stripping Length:1-15mm

Rear Sheath Stripping Length:10-100mm

Rear Core Stripping Length:1-15mm

Wire Cutting Length:80-100mm (extendable for customization)

Wire Diameter Range:OD2mm-6mm

Air Pressure:0.5-0.7MPa

Air Pressure Monitoring:Air pressure detection and alarm

Motor 6 sets of Leadshine:servo motors

Pneumatic Components:14 sets of Airtac

Solenoid Valve Domestic:12-position solenoid valve

Screw/Rail:1 set of Fulei screw / 3 pieces of Fulei rails

Module kk:2 sets of Fulei

Belt:Gates (USA)

Bearing:NSK (Japan)

Blade:High-speed steel

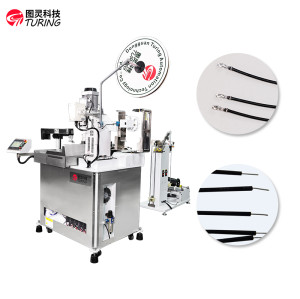

Dongguan Turing Automation Technology Co., Ltd. was founded in 2020 and is located in Dongguan City, Guangdong Province. The company specializes in the production of: fully automatic terminal crimping machines, fully automatic automatic-automatic terminal crimping and tin-plating machines, ultra-quiet energy-saving terminal machines, silent copper strip machines, computerized wire cutting and stripping machines, coaxial wire stripping machines, fully automatic nylon cable tie machines, fully automatic winding and strapping machines, computerized heat shrinkable tube cutting machines, terminal machine molds, knife molds, and new energy automatic wire harness processing equipment, etc. It mainly serves wire harness processing enterprises in the automotive, motorcycle, electronics, household appliances, electrical and other industries.

We have rich industry experience and are a trustworthy supplier. Our holding/cooperative factories are equipped with advanced production equipment and skilled front-line employees. Fully aware that the company's development depends on product innovation and quality, we have established a quality management system that meets the requirements of international quality management systems. The company continuously launches original innovations based on market and customer needs, always maintaining the novelty and innovation of products. We think what customers think and prioritize what customers need. Providing customers with excellent services and meeting their needs is our eternal pursuit!