TR-N01 Automatic Double-Head Tin Dipping, Wire Cutting and Welding Machine

- Model

- TR-N01

Item specifics

- Power

- AC220V/50HZ,

- Application

- Automatic Wire Feeding, Wire Cutting, Wire Strippi

- Feature

- Stable Performance

- Warranty

- 1year

Review

Description

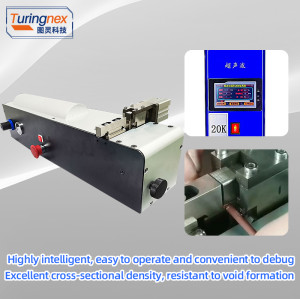

TR-N01 Automatic Double-Head Tin Dipping, Wire Cutting and Welding Machine

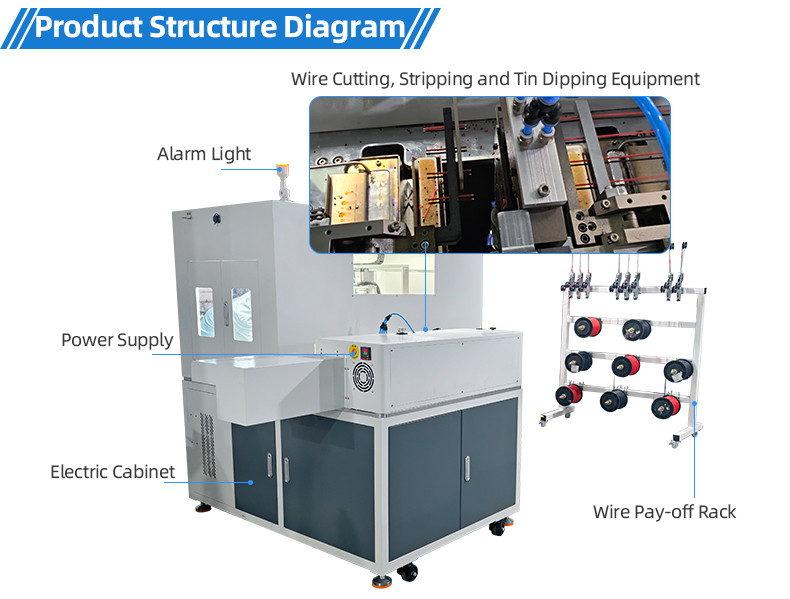

Equipment Name:TR-N01 Automatic Double-Head Tin Dipping, Wire Cutting and Welding Machine

Power Supply:AC220V/50Hz

Dimensions & Weight:2140x1580x1600mm, 700kg

Rated Power:5.5kW (Estimated)

Ambient Temperature:-5~42℃

Minimum Wire Cutting Length:25mm

Maximum Wire Cutting Length:330mm

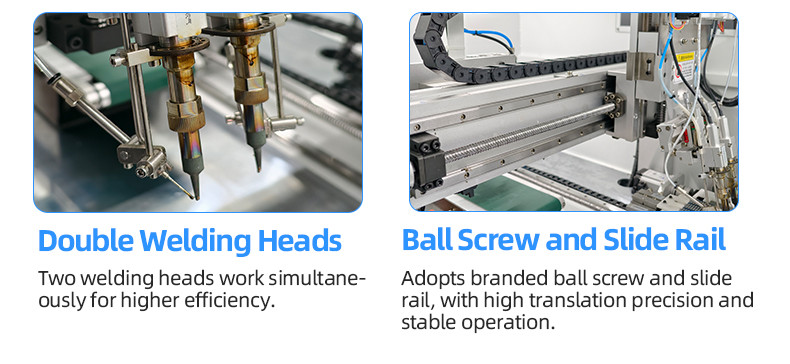

Efficiency:20000 spots / hour

Product Features

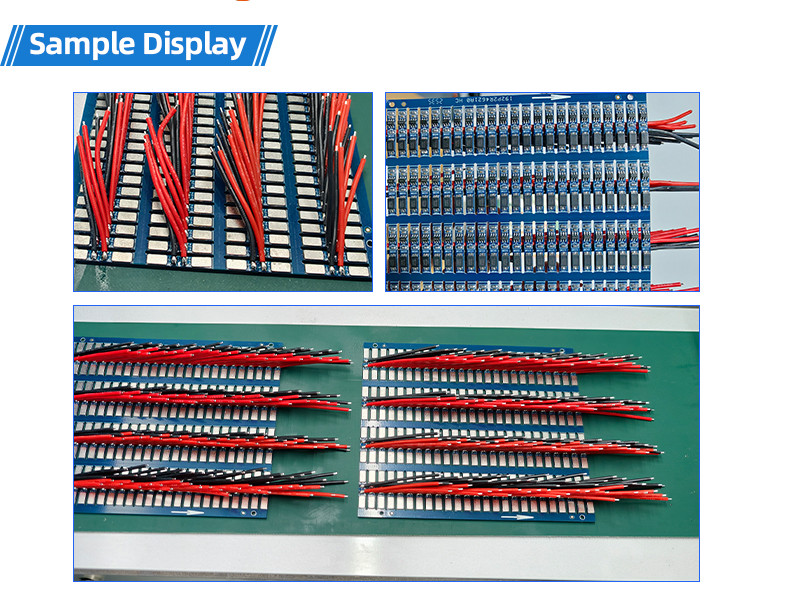

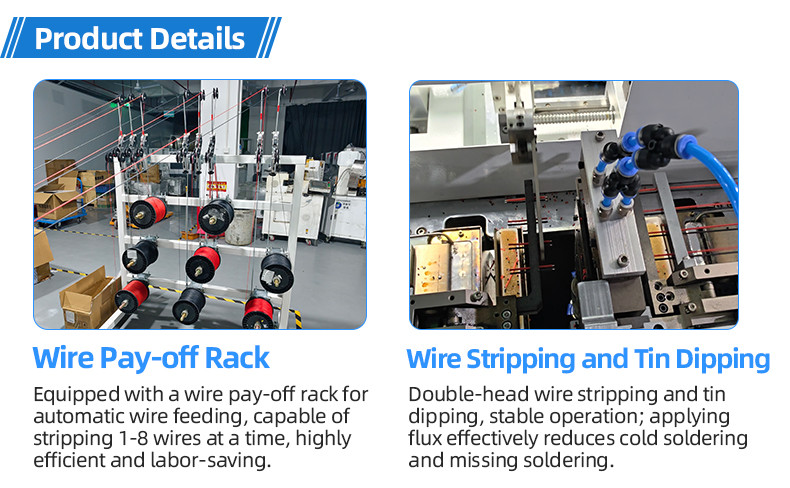

1.Equipped with automatic wire feeding, wire stripping, middle stripping (optional), wire cutting, tin dipping, and wire welding functions.

2.Can hold 8 wire spools and thread 1-8 wires (optional).

3.Strips 1-8 wires at a time, and supports free switching between 4 wire colors of the same specification.

4.The length of wire cutting and wire stripping can be freely set within the equipment's standard range. The minimum wire cutting length is 25mm, and the maximum wire cutting length is 330mm; customization is required if the length exceeds the standard range.

5.Welds 1-8 points.

6.Has the function of recipe saving and retrieval. For production changeover, only the fixture needs to be replaced, and the corresponding production recipe can be retrieved.

7.Equipment Cycle: 15,000-19,900 wires/hour.

Dongguan Turing Automation Technology Co., Ltd. was founded in 2020 and is located in Dongguan City, Guangdong Province. The company specializes in the production of: fully automatic terminal crimping machines, fully automatic automatic-automatic terminal crimping and tin-plating machines, ultra-quiet energy-saving terminal machines, silent copper strip machines, computerized wire cutting and stripping machines, coaxial wire stripping machines, fully automatic nylon cable tie machines, fully automatic winding and strapping machines, computerized heat shrinkable tube cutting machines, terminal machine molds, knife molds, and new energy automatic wire harness processing equipment, etc. It mainly serves wire harness processing enterprises in the automotive, motorcycle, electronics, household appliances, electrical and other industries.

We have rich industry experience and are a trustworthy supplier. Our holding/cooperative factories are equipped with advanced production equipment and skilled front-line employees. Fully aware that the company's development depends on product innovation and quality, we have established a quality management system that meets the requirements of international quality management systems. The company continuously launches original innovations based on market and customer needs, always maintaining the novelty and innovation of products. We think what customers think and prioritize what customers need. Providing customers with excellent services and meeting their needs is our eternal pursuit!